We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

How to pick a brake pad

When it comes to how your brakes feel, and how they work, the single part that has the biggest impact on those characteristics are your brake pads. The size and type of brake calipers and rotors that you have on your car play a part in this too. But no matter what calipers and rotors you have, when you apply force to your brake pedal, it is the pads that then have the job of making that input actually happen.

If you are looking for a new set of brake pads, your choice will typically come down to what compound of pad you want. By compound I mean the make-up of the actual material on the pad that comes in contact with the rotor. This is the material or surface that grabs your rotor and slows your car down. Every brake manufacturer typically has a range of different compounds that they offer, and when you are looking at one manufacturer to another, there are usually pretty significant differences in the makeup of the compounds used from one to another.

In short, there are a lot of choices when it comes to picking a brake pad, and that can definitely make it more difficult to find a pad that will work and perform the way that you want it to.

The is no single pad that will do everything well.

The first thing to keep in mind as you pick a pad manufacturer and pad compound is that every different pad compound is making one type of compromise or another. In terms of pad performance, you may be looking for one or more of the following characteristics:

- Low Dust

- Low Noise

- Operates in cold temperatures

- Long Pad Life

- Low rotor wear

- Good initial Bite

- Overall Friction coefficient

- High operating temperature range

- Good pad modulation

The materials that a brake manufacturer picks to blend together to create a compound are going to be based on which characteristics they want to prioritize over others, and that compound then makes a pad work a certain way.

For instance, the materials you would choose to minimize dust and noise, and maximize pad life tend to reduce the overall performance of the pad, and reduce the operating temperature as well. Conversely, the materials that give you a high coefficient of friction and a high operating temperature tend to make a lot of dust and also tend to be noisy. They also tend to have a shorter overall lifespan.

All of this is to say that it is basically not possible to find a pad that will work in freezing temperatures, not dust or make noise, have a high coefficient of friction, and also have a high operating temperature.

When you are picking a brake pad, you are going to get the best results by choosing a pad based on the type of driving or type of use you have planned, rather than hoping to find one pad that will do everything that you might want to use your car for.

How to pick a pad for the street

Generally, long life and low dust/noise are the main criteria for choosing a pad for the to be used on the street. And while many of those pads that are formulated with this in mind can cause your brakes to feel less responsive and in a few cases less than confidence inspiring. Through the years we have found a few street pads that are very civilized, but do still have decent performance characteristics in all weather conditions, etc.

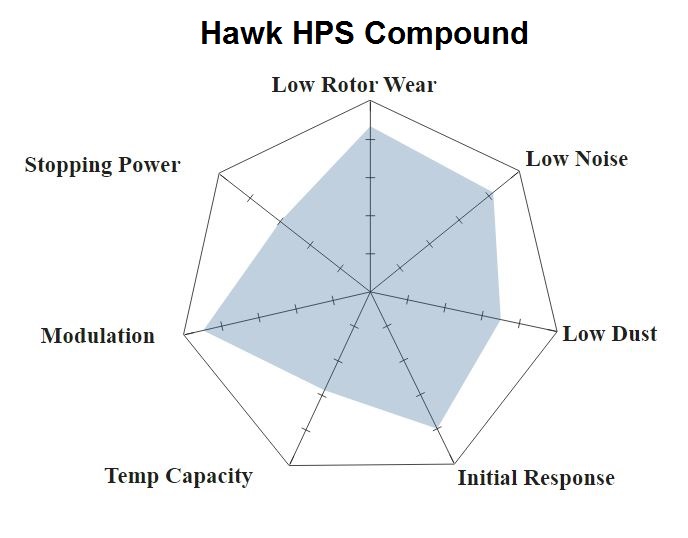

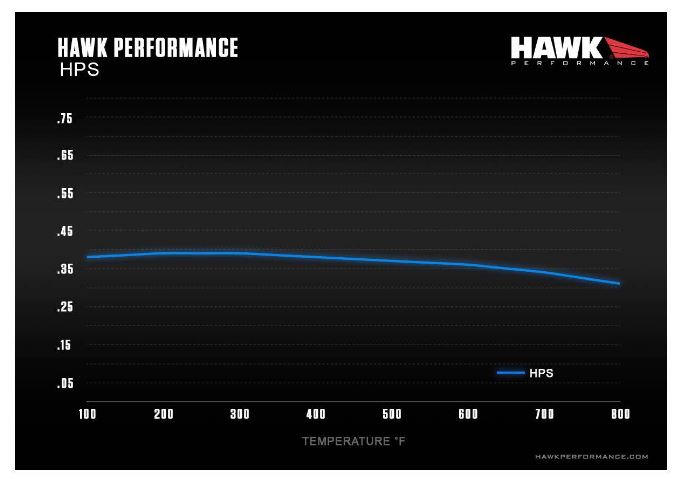

Hawk HPS (High Performance Street) compound

For a long time the Hawk HPS was our go-to pad for something that would perform slightly better than a factory pad, but kept dust and noise to a minimum. This pad works pretty well on the street, but is not something that you would want to use on track. The best characteristics of this pad is that it has very low dust and noise.

Temperature range: 100 - 700 F

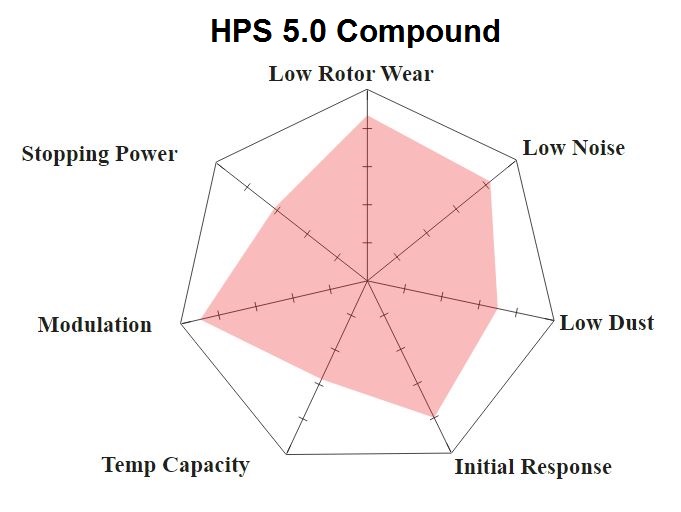

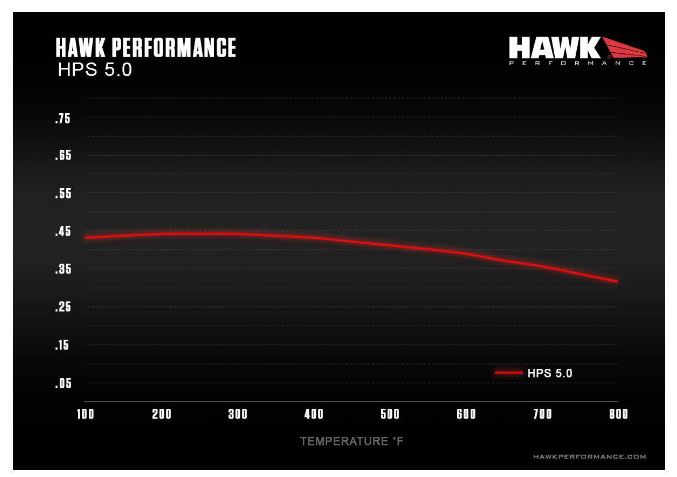

Hawk HPS 5.0 - Updated HPS compound

A few years ago, Hawk came out with a new updated HPS compound called the HPS 5.0. We have tried this compound on a number of cars, and this is now one of our preferred pad where you want a bit more performance than the HPS has to offer. The HPS 5.0 compound is still very civilized in all temperatures and weather conditions, but it offers a higher level of performance than the HPS. It does dust a bit more than the HPS, and it can start to make some noise when temperatures get below 20 deg F.

Temperature range: 100 - 750 F

Click Here for Hawk HPS 5.0 pads

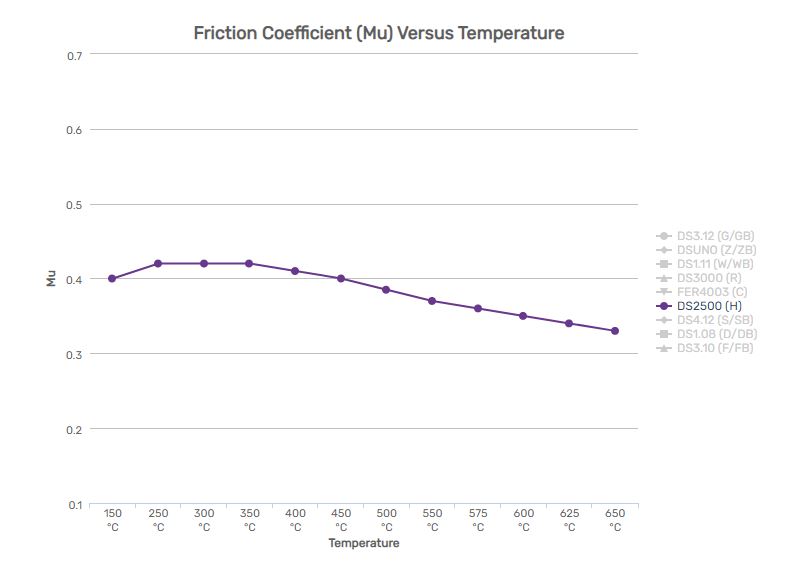

If dust is less of a concern, and you are looking for even more performance than the Hawk HPS or HPS 5.0 pads offer, the Ferodo DS2500 pads can be a good option for the street. They have more initial bite than the HPS 5.0's and they will make a little more noise in the cold, but they definitely perform better all around. And because they have a higher operating temperature, they could be use as an entry level track pad in some circumstances. This would be for lower power cars that are just running Summer tires, but not race tires, or for cars that are running large brake kits that reduce pad temperature on track significantly.

Temperature range: 32 - 900 F

Click Here for Ferodo DS2500 pads

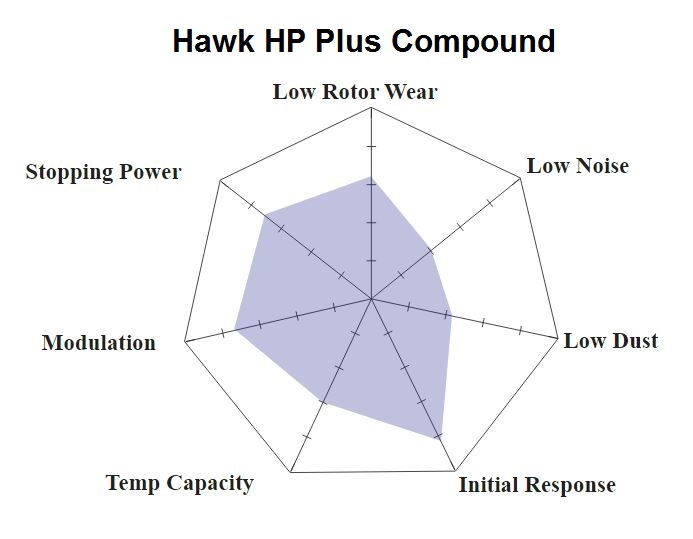

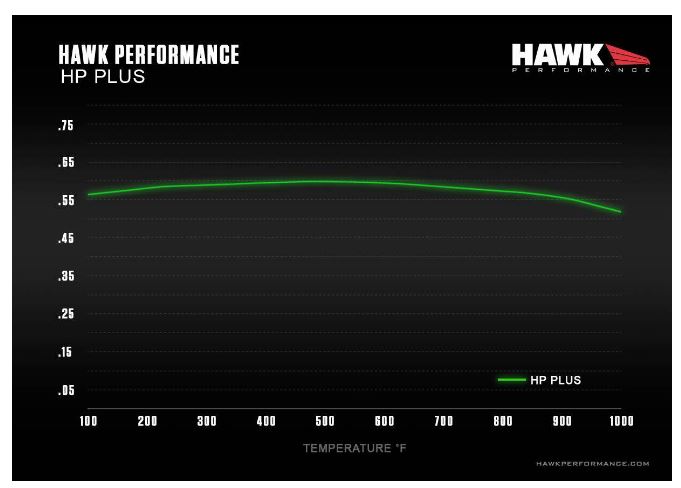

If you prefer Hawk pads, and you want something more aggressive than the HPS 5.0, the HP Plus pads are the next step up from them, and they offer similar performance to the DS2500. They do dust a fair amount, and they wear the rotors more, but they definitely offer more performance. They will work in the winter as well (I ran these year round on our 2003 WRX project car for a couple of years). Hawk does consider this an entry level track pad, though it is mainly recommend for Autocross.

Temperature range: 100 - 800 F

Click Here for Hawk HP Plus pads

How to pick a track pad

There are two basic assumptions that we are making when we start talking about track pads. The first is that you have installed stainless steel brake lines to improve pedal feedback, and you are running a higher temperature brake fluid (typically DOT 4) to raise the overall heat capacity of your braking system. You really need those two components in place as you start to go with more aggressive, higher temperature pad compounds.

Beyond that, they key consideration for this type of pad is overall coefficient of friction, and heat range. It could be that you end up having to try a couple of different compounds of pad to find one that will work with the type of driving that you are doing and the type of tires you are running. the more aggressive you are on the brakes, and the stickier the tires that you run, the more heat you will be able to put into your brakes.

A word about the life of track pads

When you are running pads at the track, life is not measured in miles. More typically it is measured in time on track, or number of track days before the pads need to be replaced. And in terms of thickness, because track pads will be getting much hotter and used much more aggressively than a street pad, you may want to replace track pads long before you would replace your street pads.

A rough rule of thumb is your pads have gone through 3/4 of their life when the pad thickness is half of what it was new. The reason for this is that as the friction material thins, more and more of the heat that the pads and rotors generate is going to work through the pad compound, and into your calipers, etc. That additional heat can wear down the pad compound faster as it thins out, and that can lead to faster and faster wear.

In short, you definitely want to keep a close eye on your pads when they get down to 1/2 of their original thickness, and definitely replace them well before there is only a couple of millimeters of pad compound left. If you do end up wearing through all of the pad compound on track, and end up with only the metal backing plates left to press against the rotors to stop your car, your stopping power is going to be significantly reduced, and the chances of sparks etc. causing issues if you do end up off track goes way up.

It just isn't worth the risk.

How can you tell if you overheated your pads?

Especially when running a brake compound with a high operating temperature with sticky (R-Compound tires), you are going to be putting a lot of heat into your brakes. When you start running your car this way, you need to keep an eye on your brakes and brake system to make sure you aren't significantly overheating it. A spongy pedal (brake fade) can be one sign that the brake system is overheated, but with higher temperature fluid, or with a brake kit that has a much higher temperature capacity than street calipers, this may not be enough of an indication.

The two main signs that you want to look for are burnt paint on your backing plates, or a burnt or ashy appearance of the pad compound, and melting of your calipers dust seals (if they have them). If you see those signs, they are definitely a good indication that your brakes are getting very hot, and you may want to look at either changing the compound of pads you are looking, going with a larger brake kit that has a higher heat capacity, and possibly cooling ducts for your brakes if you haven't put them on all ready.

The first reason that this can be cause for concern is that various pads will behave differently when they are overheated. Hawk pads (in our experience) tend to transfer larger amounts of pad compound to the rotors, which can cause a lot of pedal and wheel vibration as well reduced stopping capability. Ferodo pads (in our experience) will still work when overheated, but tend to wear much more quickly.

Basically, the characteristics of the pad can change dramatically when they are run well outside of their designed heat range, so you then have to pay close attention to your brakes as you continue to use them. At an extreme, those changes in the way that the pads work could potentially lead to a safety issue on track if the brakes end up failing.

Our recommended track pads

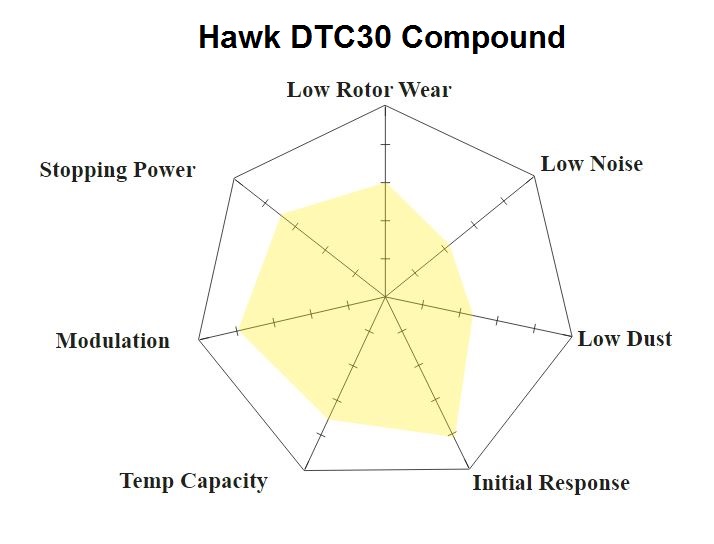

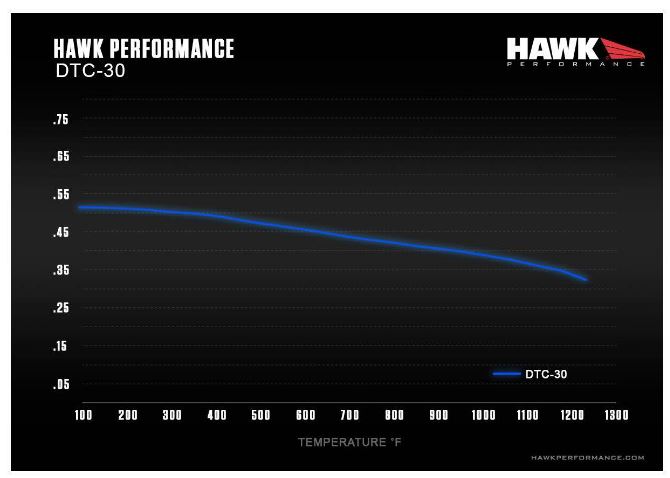

We ran the Hawk DTC30 pads in our Pikes Peak car for a number of years. One of the main reasons that we selected this compound was because it was available in a good number of pad shapes, and it started to work at a fairly low temperature for a track pad. This gave us good performance even when cold, and these pads worked well up to the point where we overheated them. The main issue we ran into with this compound specifically was as we moved to sticky R-Compound tires, it was fairly easy to overheat them, and once that happened, the pads were ruined and there was a lot of vibration in the brakes because of the pad compound transferring to the rotors.

This is a good pad compound for a lower power car, or if you are using something like high performance summer tires. If you move to race tires, you may want to run a more aggressive pad.

Temperature range: 100 - 1200 F

Optimal temp range: 100 - 800 F

Click Here for Hawk DTC30 Pads

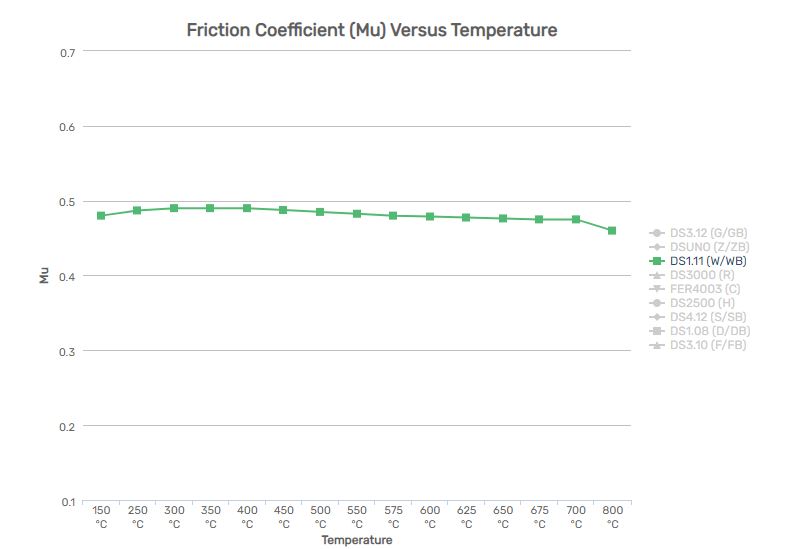

The Ferodo 1.11 pads would be a step beyond the DTC30, but they still work well even on your first lap on track. They are more of an endurance pad, and they have good initial bite, and they are fairly linear. The more pressure you apply, the more stopping power you get.

This is a good option if you have a lower power car (sup 400 whp) and are running race tired, and or a good brake kit that has good heat capacity.

As another point of reference, now that we went up to the RCM Alcon 365mm front brakes on our Pikes Peak car, we are running the Ferodo 1.11 pads front and rear and they work great on Pikes Peak or at the track on R-Comps.

Temperature range: 390 - 1380 F

Click Here for Ferodo DS 1.11 Pads

G-Loc R-12 and R-10 compound

If you are looking for a step up from the DTC30 pads, you should consider running G-Loc R12 pads up front, and G-Loc R-10 pads in the rear of your Subaru. With these pads, a staggered setup is recommended for Subaru's because the rear pads take a lot longer to heat up, and typically don't get nearly as hot as the fronts.

The G-Loc R12 compound falls in between the Hawk DTC30's and the DTC60/70's. The main advantage of the G-Loc pads is that they don't wear the rotors as aggressively as the Hawk pads, and they offer much better pedal modulation compared to the Hawks.

R-12 temperature range: 173 - 1860 F

Click Here for G-Loc R-12 Pads

R-10 temperature range: 118 - 1475 F

Click Here for G-Loc R-10 Pads

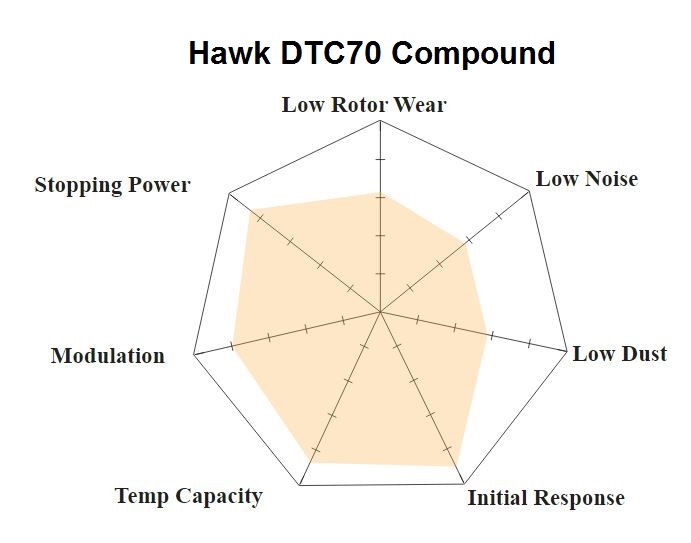

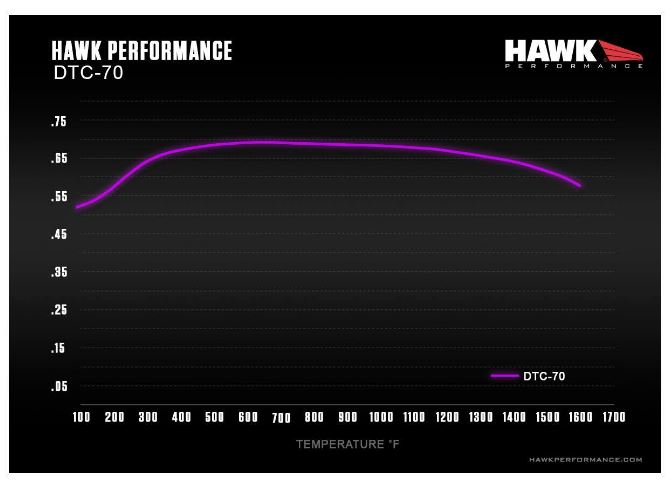

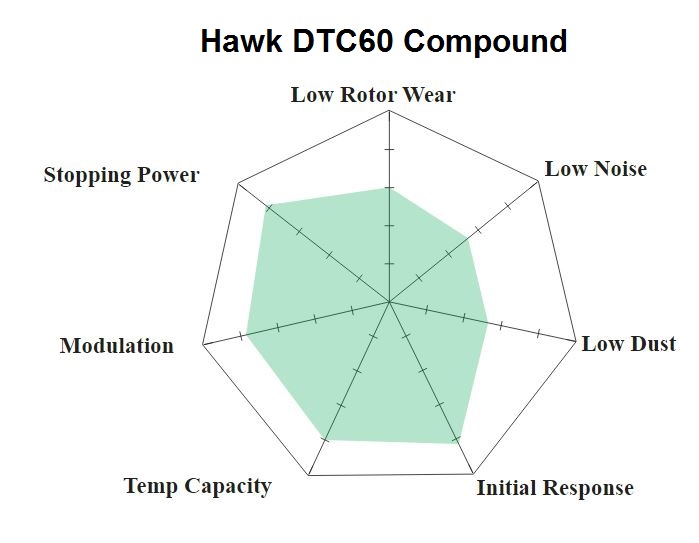

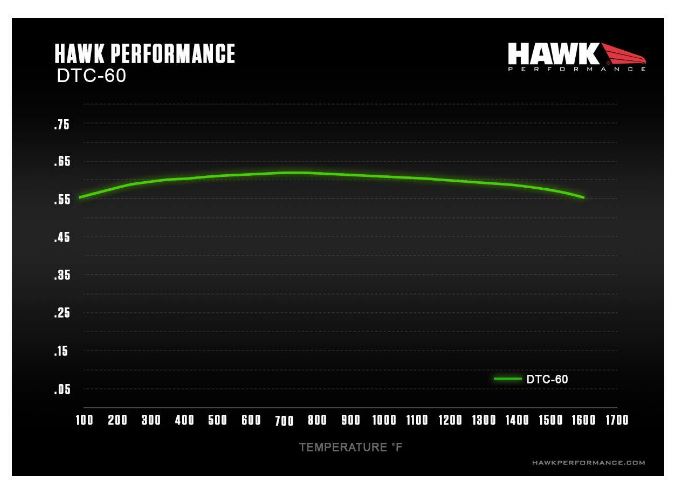

Hawk DTC60 - DTC70

If you want to stay with the Hawk pads, and go up from the DTC30's, your best bet in a Subaru is to go up to Hawk DTC70 pads up font with DTC60 pads in the rear. These pads have much higher operating temperature than the DTC30's, and because they do need heat in them to really start working, it is recommended to run a slightly lower compound in the rear because they won't get as hot as the fronts.

This combination will give you a ton of stopping power, and high heat capacity. We have ran these on track with good results using race tires.

The main down side to the Hawk DTC70/60 pads is that they don't have as much modulation as the G-Loc or Ferodo pads, and they wear the pads and rotors fairly quickly.

They do provide a significant amount of stopping power though.

As a quick note, if you didn't want to take this big of a step up, you could try DTC60 pads up front with DTC30 pads in the rear. But at that point you may be better off looking at the G-Loc R12/R-10 pads or Ferodo 1.11 pads.

DTC70:

Temperature range: 400 - 1600 F

Optimal temp range: 800 - 1200 F

Click here for Hawk DTC70 Pads

DTC60:

Temperature range: 400 - 1600 F

Optimal temp range: 700 - 1100 F

Click here for Hawk DTC60 Pads

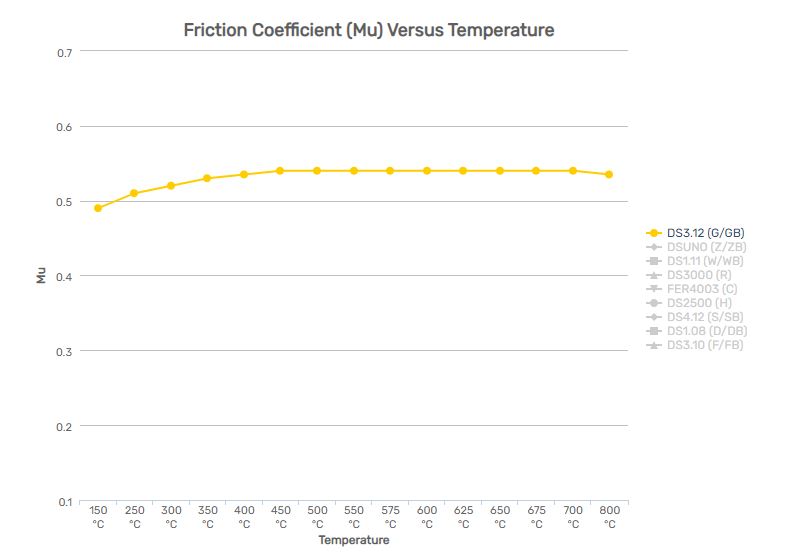

The Ferodo DS 3.12 pads are just like the Ferodo 1.11 compound, but better in every way. They have better initial bite and higher overall coefficient of friction than the 1.11 pads, and have a higher operating temperature as well. They are also much easier on rotors compared to the Hawk DTC70/60's.

Nigel has been running these on his race car and loves them.

They are also very linear through their optimal temperature range.

Temperature range: Max temp 1560 F

Click Here for Ferodo DS 3.12 Pads

The G-Loc R16 compound is roughly equivalent to the Hawk DTC70/60 pads. The main advantage that G-Loc has is that they have much better pedal modulation than the Hawk pads, and they will not wear your rotors as aggressively.

For Subaru's you would most likely want to run the R-16 compounds up front and R-12's in the rear.

Temperature range: 255 - 2000 F

This covers the majority of the various pads that we have tried so far, and as we try anything else, or any new compounds, we'll do our best to add those results to this blog as well.

Hopefully this helps, and thanks for reading!

- Jon Cooley