We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Subaru EJ Turbo Timing Component Upgrades

The timing components, from the belt to the idler pulleys to the hydraulic tensioner, are pretty much all the same for all of the Turbo Subaru engines that we have had here in the US. That means that most all of the upgrade options for the EJ257 can also be applied to the EJ205 or EJ255. For this post, we wanted to take a look at those options and give you the information that you need to get the right parts for your application, no matter which engine you have.

Small Idler Pulley

The first upgrade worth mentioning is the small idler pulley if you have a 2002 - 2003 WRX only. Initially, Subaru used a small idler with a single bearing in the middle, and it was prone to fail. For that reason, starting in 2004, All Subaru EJ Turbo Engines started to use a small idler with two bearings in it which made the pulley much more reliable.

The good news is all that is required to update one of the early cars to this a longer bolt to attach it to the engine.

This is such an improvement, we only sell timing kits that use the updated double bearing small idler pulley.

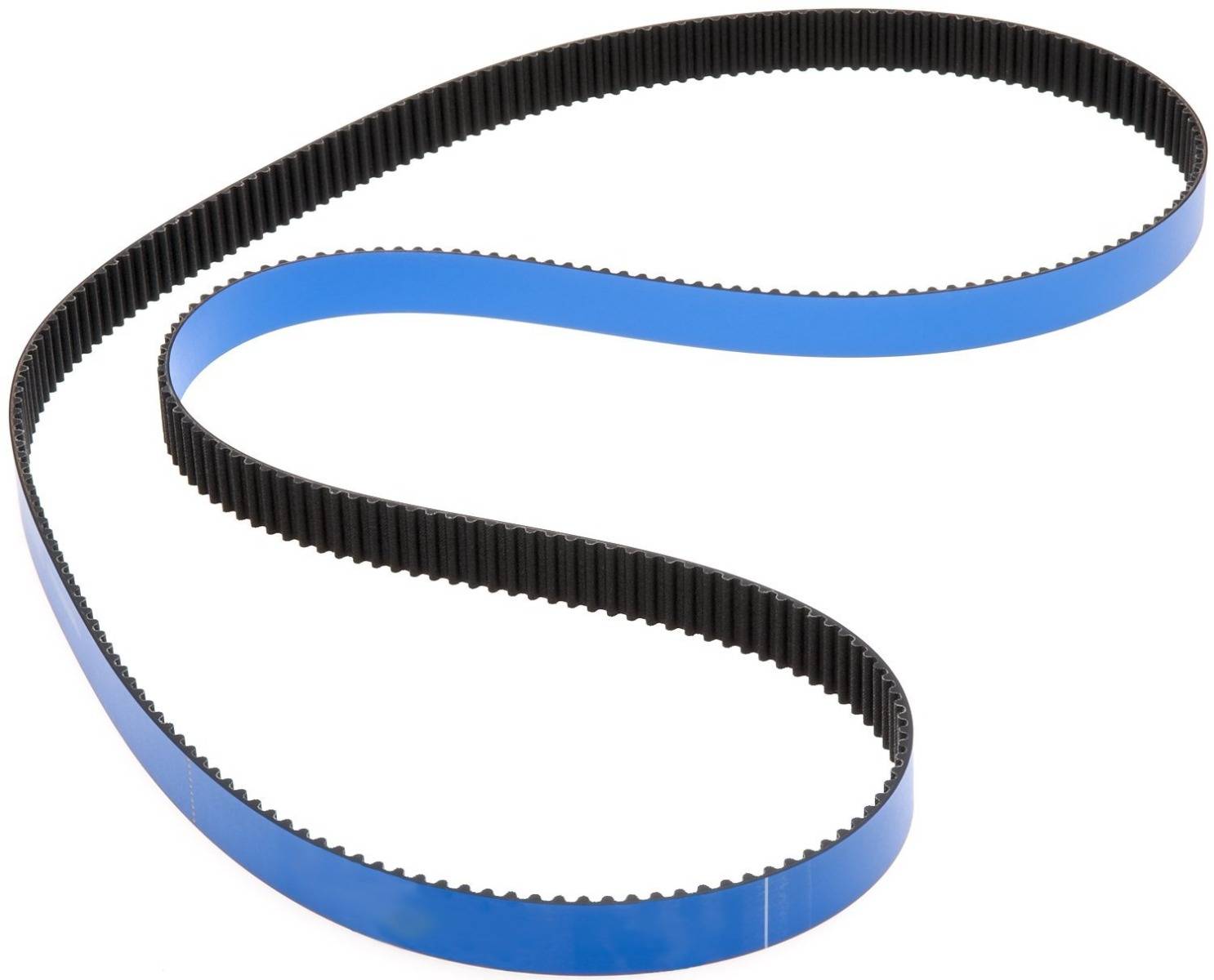

What is the difference between Subaru Timing Belts?

The timing belt used between the EJ205, EJ257, and EJ255 has the same fitment, and the same timing marks are used for all of these engines. The OEM timing belt is reinforced with cotton, or cotton like fibers. For stock applications, and mildly modified applications, the stock timing belt is perfectly sufficient. But if you are making a lot more power than stock, and especially if you are revving the engine higher than the stock rpm range, it is a good idea to use a timing belt that has better reinforcement than stock.

The reason for this is largely the length of the belt used on the Turbo Subaru EJ engine. It is easily 2 - 4 times longer than a timing belt that you would find on most other 4-cylinder engines. And beyond that, you are turning 4 cams instead of 2 on the Dual Overhead Cam Subaru engine because there are 2 separate cylinder heads. This means that the stress on the belt itself is greater, and if there is even a small amount of stretch in the belt (Say .5%), that stretch will translate in a larger variance in valve timing compared to that same stretch in a belt that is much shorter in length.

The most common timing-belt upgrades are either the Gates Racing Timing Belt, or the HKS Timing Belt. Both of these are reinforced by aramid and or nylon fibers. These fibers reduce the chance that the belt will stretch significantly, and over the life of the belt, will keep your engine running closer in time to when the belt was first installed. Gates makes both their belt which is said to be 300% more durable than OE, as well as the HKS belt which is said to be 400% more durable than OE.

Click Here for the Gates Racing Belt

Click Here for the HKS Timing Belt

It is also worth mentioning that the belts are blue or purple respectively, and it is not unusual for some of that paint to come off as the belt is used, and sometimes that paint can stick to some of the smooth pulleys. This doesn't affect the belts function because the smooth pulleys movements are not indexed.

There is also the STI Kevlar timing belt which is Kevlar reinforced. From our experience this is the most durable of all of the optional timing belts, and tolerates high rpm and high power the best, and it was developed originally to be used on Subaru's WRC car.

What is an Eccentric Idler Pulley and when do you need it?

When you are installing a timing belt there are markings on each cam pulley that have to be properly aligned, and there also marks on the cam pulleys that correspond to specific marks on the timing belt to ensure that the cams and engine are in proper time. Once you have everything set, and you rotate the engine around, it is not unusual to see a slight variance in the alignment of the cam pulleys. It would typically fall into roughly 1/8th to 1/4th of a tooth mis-alignment on one side of the engine or the other. This is normal, but if you are using cylinder heads (or a block for that matter) that has been decked, or especially thicker head gaskets that stock, that variance can increase, though it is virtually always less of a variance than 1 tooth on the timing belt.

This means that you can't move the timing index on any of the pulleys by one tooth to get the cam pulley alignment to fall back into a more precise alignment.

When needed, this is where eccentric idler pulleys give you the ability to apply a fine adjustment to the timing belt to precisely set the cam pulley alignment on either side of the engine.

For largely stock cars, this fine adjustment is not typically needed, but on high performance engines, or in situations where a thicker head gasket is used, that fine adjustment can help make sure that the timing of the engine is properly set.

The majority of the eccentric pulleys available use a single bearing in the pulley which have a service life of roughly 60,000 miles, and are not ideal for high rpm, high power applications. Roger Clark Motorsport now offers a dual bearing eccentric idler pulley, and that is a more ideal design in terms of service and high rpm use, etc.

When do you need to upgrade your Timing Belt Tensioner?

The factory Subaru Timing Belt Tensioner uses a single vertical hydraulic element to maintain tension on the belt. It is made by NTN, and it is adequate for applications from stock up to moderately modified engines. The one thing that is most significant about the OEM timing belt tensioner is that it cannot easily be re-compressed to be reused. There are actually 2 pages in the Subaru Service manual detailing how the tensioner needs to be properly re-compressed, and it involves a vertical press with a strain gauge to ensure that a specific amount of pressure is used to re-compress the hydraulic cylinder.

Click Here for the Subaru OEM Timing Belt Tensioner

For this reason, the best tensioner to use in most applications is a new tensioner. But for high rpm use, or for very high power use, it is better to use an upgraded tensioner.

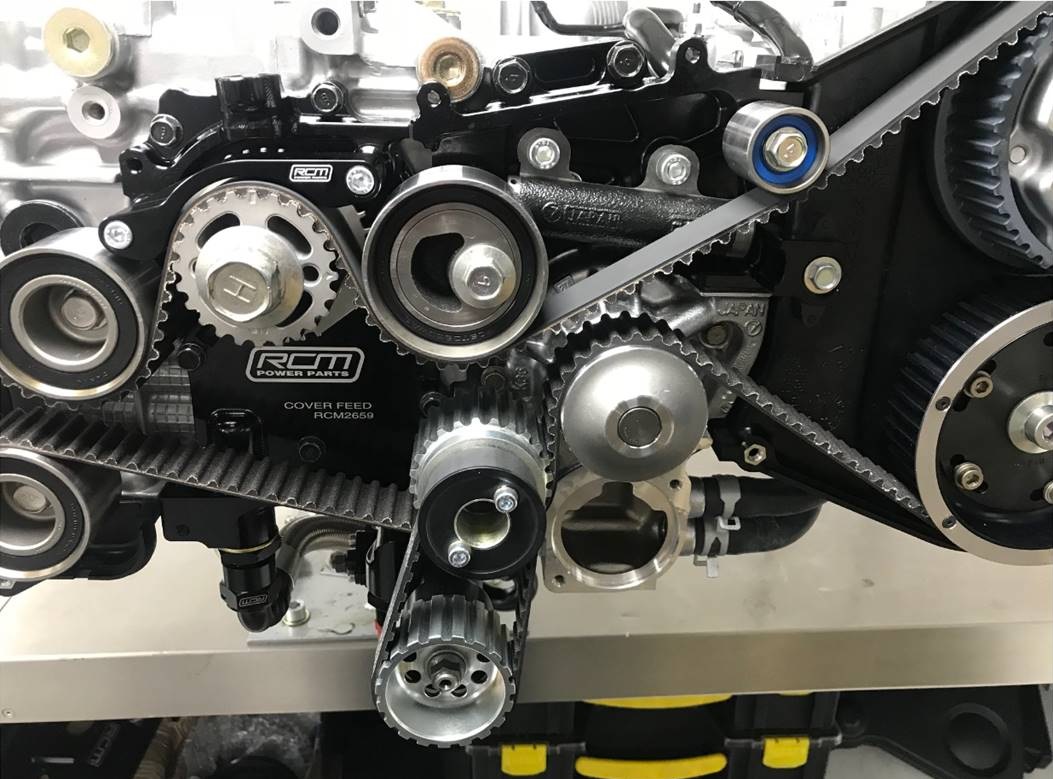

What is a High Grip Tensioner?

Roger Clark designed a version of the "high Grip" tensioner, which was originally developed for use on the Subaru WRC Rally car in the late 90's on. It uses the older style (1998 and older) Subaru OE horizontal hydraulic tensioner with the small idler pulley which was missing on Subaru's original design.

This results in a tensioner that is very robust, prevents issues with belt slap because of the inclusion of the small idler pulley, and can be easily re-compressed for re-use due to the larger horizontal hydraulic tensioner.

Click Here for the RCM High Grip Tensioner

For an in-depth look at the Eccentric Idler pulleys and the Roger Clark High Grip Tensioner, take a look at the video that we put together with Tasso from OTC Racing and Ryan from DSX Motorsports:

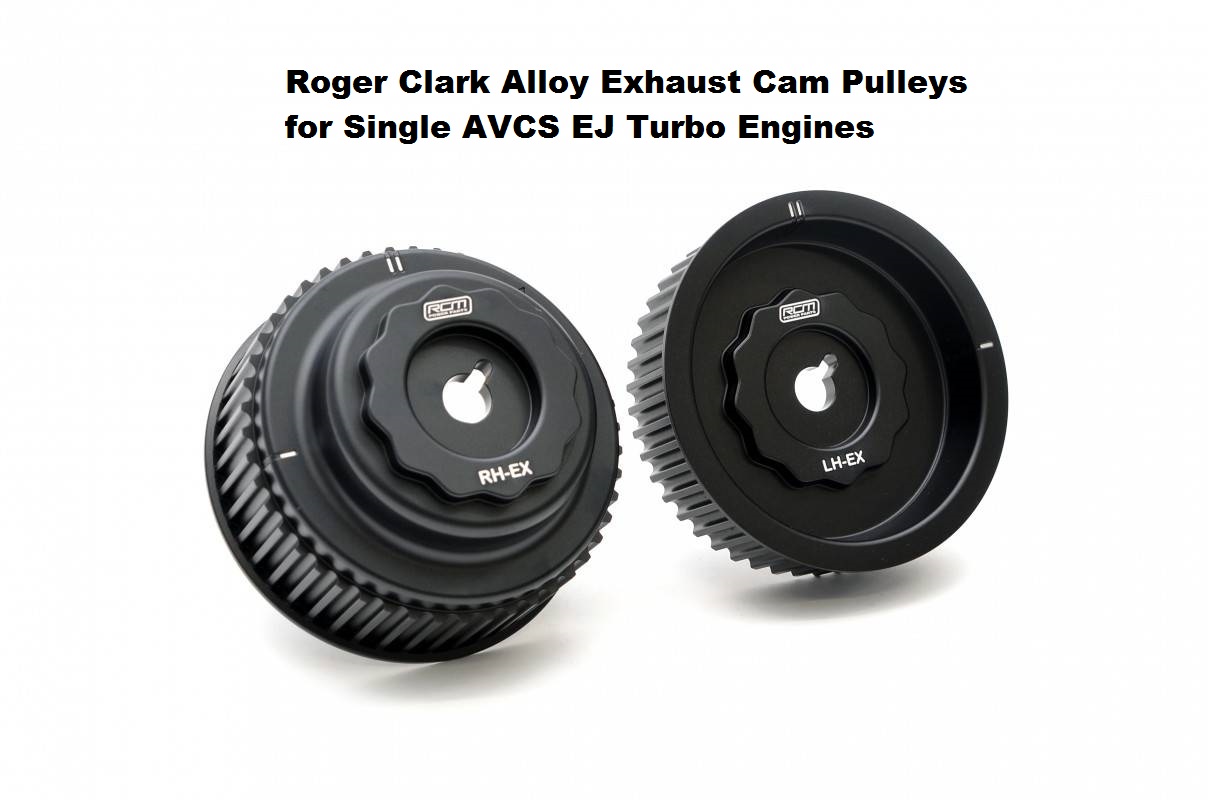

When do you need to upgrade your cam pulleys?

For most applications, the OE cam pulleys are perfectly fine. Any factory cam pulleys that are metal, as the left-hand intake non-AVCS pulley, or any of the AVCS cam pulleys have proven to be very reliable.

The first point that you might want to upgrade your cam pulleys is if you are running aftermarket camshafts, and/or you are building a race engine where you want to maximize your cam performance at a certain rpm range. To do this you would need adjustable cam gears which allow you to index the cams. These adjustable gears require proper set-up which would only be recommended to be done by an experienced professional.

Click Here for RCM Steel Adjustable Cam Pulleys

The other advantage of an adjustable cam pulley is that it is more robust than the OEM composite plastic cam pulley.

Roger Clark Motorsport has built countless higher power non-AVCS Subaru engines, and one thing that they noticed was that for high rpm use, and especially when using an aggressive cam with high lift and stiff valve springs, the stock composite plastic pulleys were not as reliable as they would like. Most of the time, this resulted in them replacing them with a set of adjustable cam gears, but recently they became aware that many people didn't want the complexity that came with those adjustable gears. They just wanted to improve reliability over the stock plastic ones.

So now Roger Clark offers Alloy cam pulleys for both the non-AVCS and Single AVCS Turbo Subaru engines.

Click Here for the Non-AVCS RCM Alloy Cam Pulleys

Click Here for the Single-AVCS RCM Alloy Cam Pulleys

I hope that this helps, and if after going through all this you still have any questions, please feel free to contact us through Live Chat, and we'll do our best to answer any other questions you have.

Thank you for reading, and Stay Tuned!

- Jon Cooley