We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

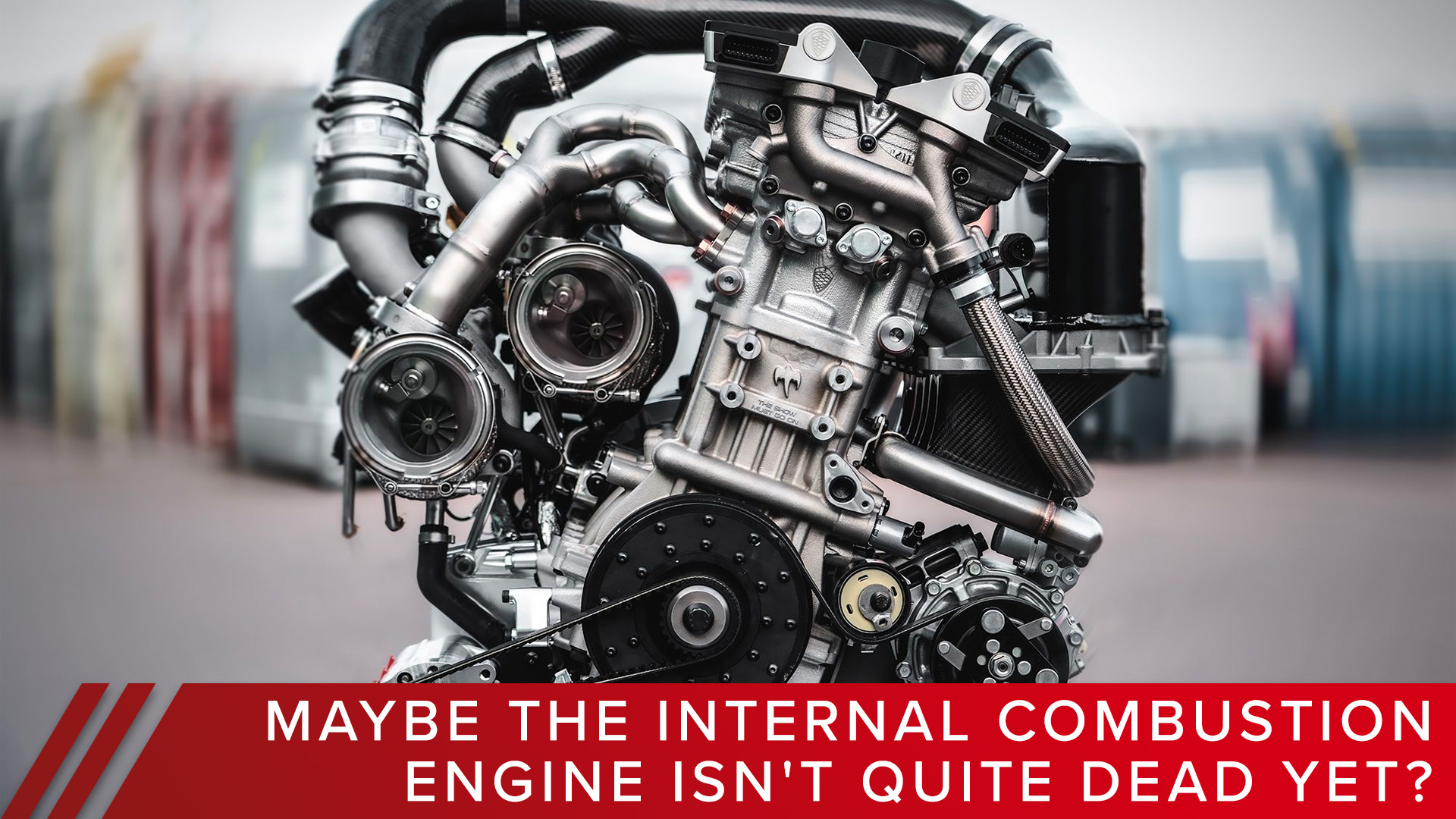

Maybe the Internal Combustion Engine isn't quite dead yet?

If there is one constant in the automotive industry, it is that there is never a shortage of ideas to solve a problem. And sometimes, the bigger the problem, the wilder and crazier the ideas get to solve it.

If you have ever heard of Christian Von Koenigsegg, and his car company Koenigsegg, the most likely you are aware that he has built a truly amazing Super Car company on making wild and crazy ideas work. Just one example is the Koenigsegg Direct Drive system that first appeared in the Regera. That car was able to reach a 248 mph top speed, and it only has 1 gear.

How does that work? I have watched the video a number of times describing it, and I have no idea. But it works, and it apparently works really well.

But more than likely, you have not heard of Freevalve. This is a sister company to Koenigsegg, and their goal has been to revolutionize the traditional valve train of the internal combustion engine.

The first production car to use this technology was just unveiled, and it is the Koenigsegg Gemara.

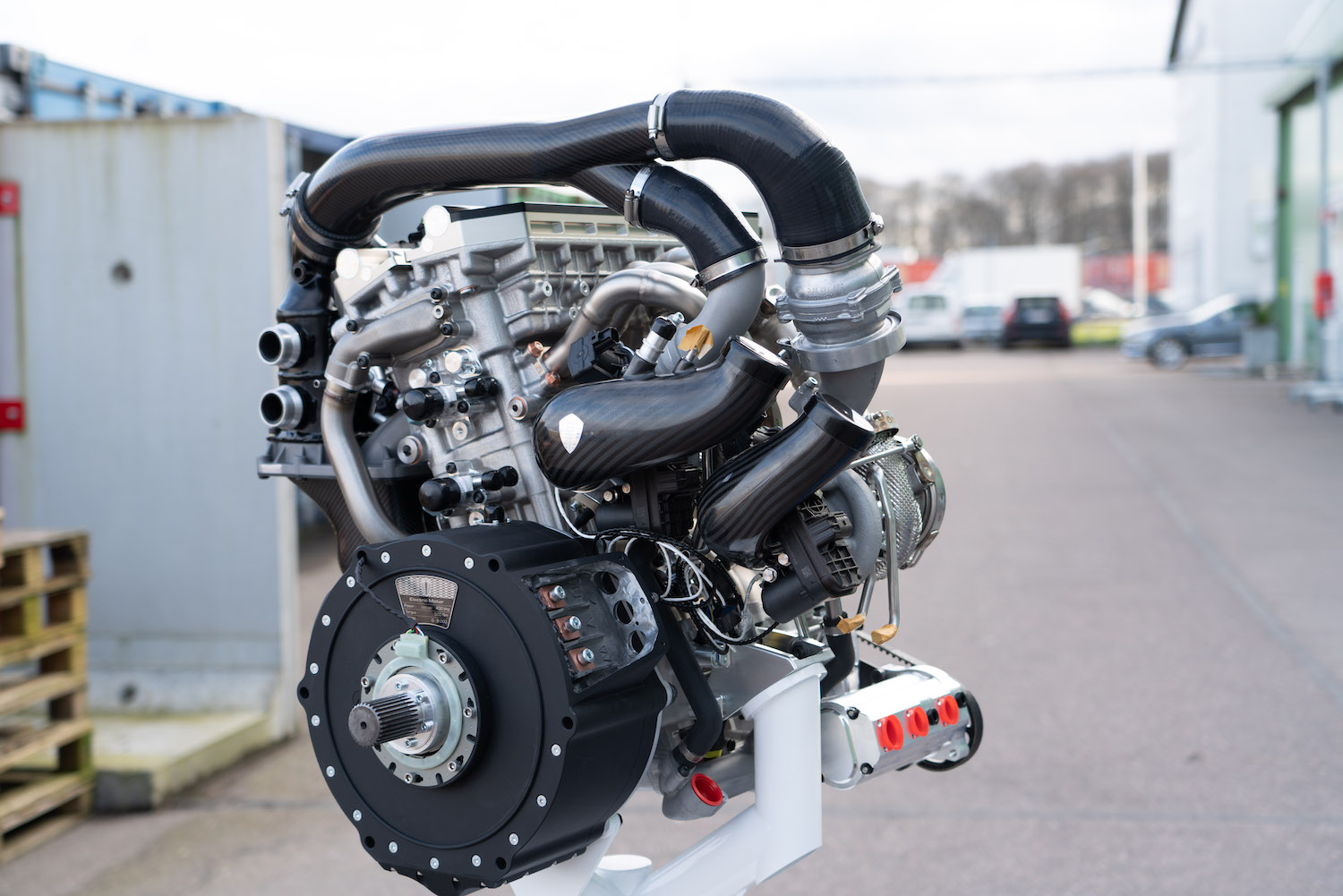

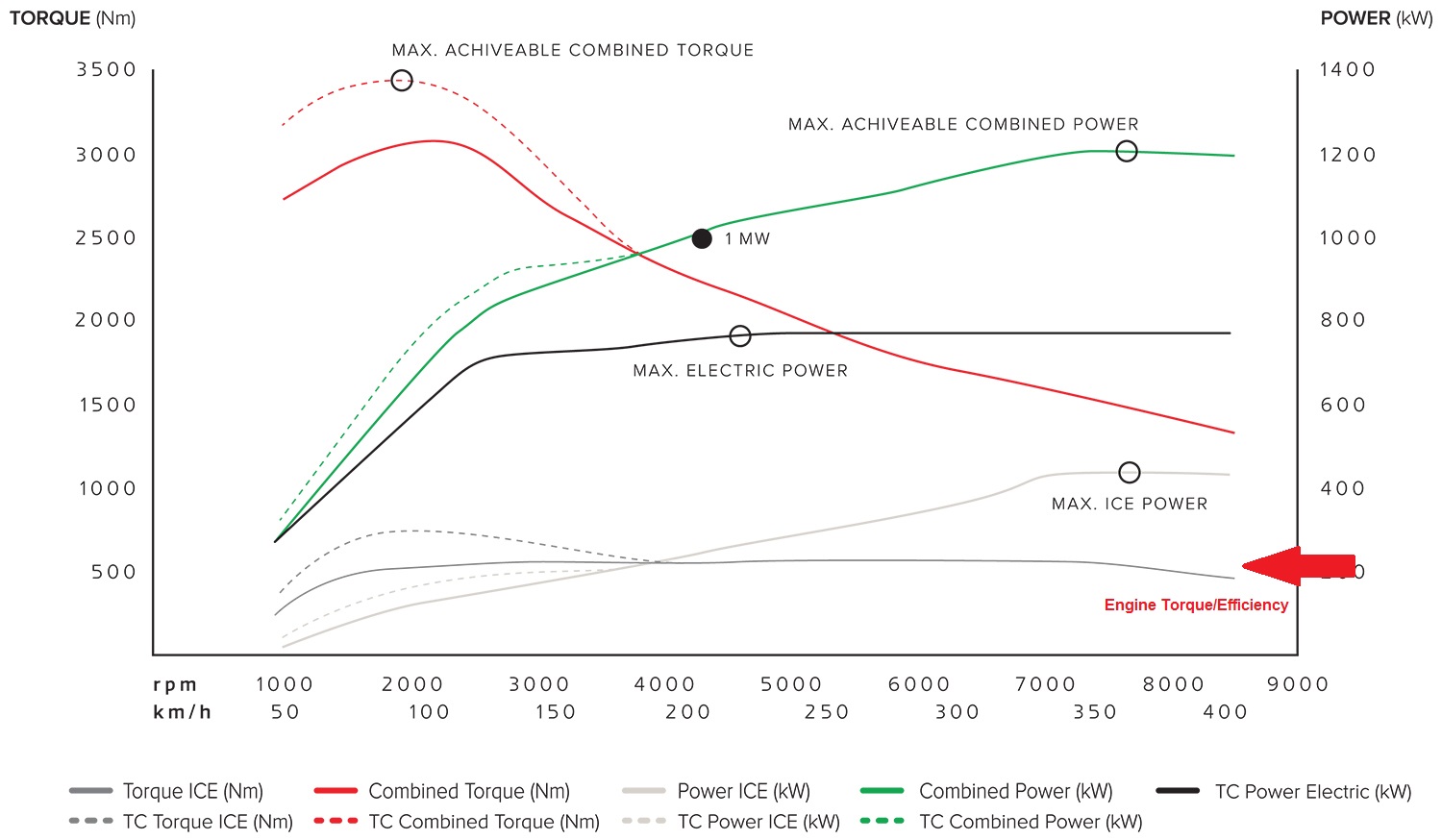

This car makes a ludicrous 1,700 hp, most of it from electric motors. But what I want to draw your attention to is the 2.0 liter, 3 cylinder (yes, 3 cylinder), twin turbo internal combustion engine that makes 600 horse power. What makes this all possible is the Freevalve cylinder head.

To put it simply, the Freevalve system puts solenoids in control of every valve. This eliminates, the timing belt, camshafts, cam gears, and any engine power that would be needed to drive those things. In its place you have a bunch of solenoids that are infinitely controllable. Basically you can optimize the engine to run exactly how you want it at virtually any rpm.

With the engine in the Gemera, this is demonstrated in two significant ways. The first is how they get the twin turbos to work. Each exhaust valve has its own port, and of the 6 valves (3 cylinders remember), 3 go to one turbo, and 3 go to the other. But they aren't driven the same way. At lower rpm, only 1 valve per cylinder opens, sending all of the exhaust gas to a single turbo. Then as rpm and power demand increases, the other valve opens to drive the second turbo. This is how such a small engine can drive two turbos, and make huge power.

The second detail is in how flat the torque curve is for this engine. And it is basically completely flat. The torque that you see on a dyno-sheet is a measure of an engine's efficiency, and typically there will be a short peak where the engine is most efficient. This is tied to cylinder-head design, and the cam profile, but in a typical engine, you will only see peak efficiency for a small rpm range. Developments like VTEC, AVCS, etc. have increased this range, but Freevalve means that the engine, even driving one, then two turbos, can nearly always operate at peak efficiency.

This technology is certainly new, and no doubt expensive at the moment, but possibilities of what this could do for the overall efficiency of the internal combustion engine long term are huge. Current F1 engines are now just getting past 50% efficiency, but it might be possible with the level of control that Freevalve brings to get that level of efficiency to trickle down to everyday road cars.

Honestly, the thought of what could be done with this system on a Subaru engine, or an in-line 4, etc., is mind boggling. With any luck, the rest of the automotive manufacturers are aware of what Koenigsegg is doing, and would be willing to try this technology out in a more mass-market vehicle.

- Jon Cooley