We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

A look at the Gobstopper III build by Roger Clark Motorsport

Roger Clark Motorsport has built two cars that not only established them in the Subaru world, but each of these cars almost re-defined what the Subaru WRX and STI platform was capable of. The first of these was Gobstopper I that wes build back in 2006.

Gobstopper I was built on the GC Impreza chassis, and to say that Roger Clark went all out on the development of this car is an understatement. The short version of the modifications to this car is that it is running an EJ20 engine making 850 hp, and a sequential transmission. RCM developed the suspension and brakes as well to turn this GC into an all conquering Time Attack car.

Then, in 2009, RCM started work on Gobstopper II. This was based on the GR chassis, and what sparked the development of this car was when Prodrive gave Roger Clark Motorsport the opportunity to get one of the last shells that it had built for the Subaru WRC effort that was never used because Subaru left the WRC.

With a Prodrive shell ready to build, Matt and Olly Clark were able to take everything that they had learned with Gobstopper I, and apply that to building Gobstopper II. GSII used the familiar EJ20 engine and sequential transmission, but with this new chassis, a lot more work was done with composite materials and aerodynamics to help get the power to the ground. When Gobstopper II was finally done, it took the torch from GSI, and Olly Clark and Roger Clark Motorsport continued to dominate the UK Time Attack Scene wining multiple races and championships.

Gobstopper II even held the overall record time at the Goodwood Hillclimb for a time.

But starting a couple of years ago, Matt Clark and Roger Clark Motorsport wanted to push the Subaru platform even further than what they were able to accomplish with Gobstopper II, and work on Gobstopper III began. There has been a ton of work and development put in to Gobstopper III, and it is about to be revealed!

But before RCM takes the cover off of GSIII on December 25th, 2019, they are letting us in on all of the fine details that went into making this car, and we are going to go through them all here!

In this first picture, we can see the exhaust manifold for GS3. They are using a rotated Precision turbo, and there also looks to be an anti-lag valve plumbed into the header as well.

One of Roger Clark Motorsport's most valued technical partners is Alcon. For Gobstopper III, Alcon Specialist Brakes & Clutches engineering masterpiece of a clutch! Boasting a torque capacity rating of 826 lb.ft/1120Nm this 140mm quad plate carbon/carbon system is more than capable of handling whatever RCM can throw its way!

Weighing a featherweight 2.42kg it’s engineered to absolute perfection and combined with a custom made 185mm 0.7kg titanium flywheel will mean the engine has far less mass to spin than anything RCM have ever used before!

Hot on the heels of the picture of the amazing Alcon Carbon clutch comes the answer to the many questions you probably had regarding how will the starter and gearbox be configured on Gobstopper III???

The car will run a totally bespoke 6 speed sequential transmission incorporating an active centre diff with billet casing and bell housing. This also mounts the 1.4Kw starter motor for seamless interaction with the titanium flywheel assembly. Using a fully custom built system allows us to position the engine and transmission exactly where RCM need it to be for optimum weight distribution.

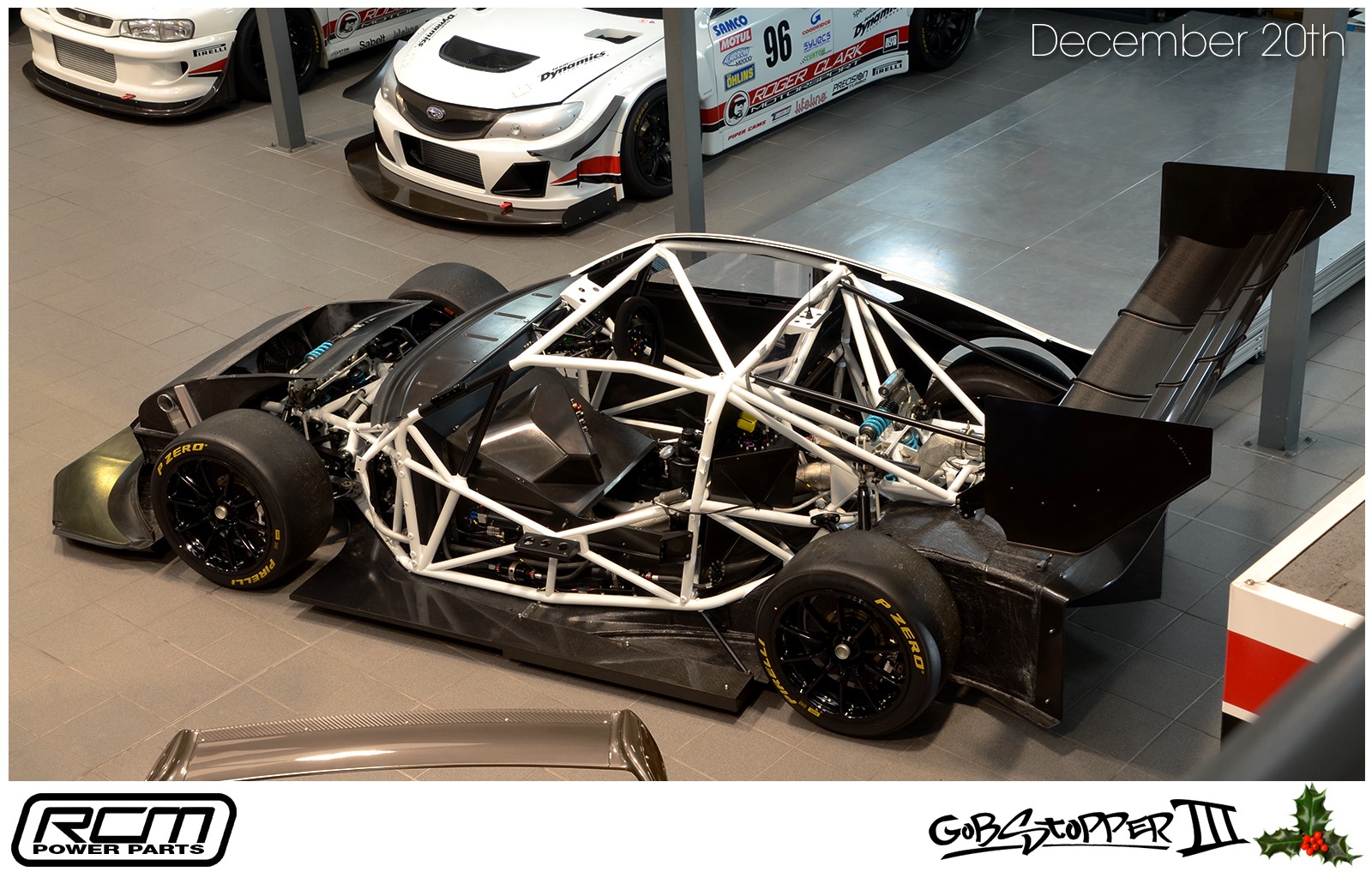

Picture 4 of Gobstopper III is a vivid demonstration of how one of the primary targets of this particular project was to substantially reduce weight when compared to the previous Gobstopper race cars.

The complex latticework of 142 CNC laser cut T45 steel tubes in 1 to 1.5mm thick gauge are painstakingly TIG welded together to create an overall chassis weight of just 130kg whilst still offering unrivalled structural rigidity and safety for the driver.

Once the chassis design had been finalized the computer model was run through a crash test simulation by leading automotive and engineering consultants MIRA in order for it to be granted FIA certification. Exceeding the test criteria by a huge margin is testament to the many hours of skilled craftsmanship which has gone into this vital part of the project.

With the biggest single saving in weight of over 220kg compared to the chassis used in Gobstopper II, RCM now have the perfect foundation to build on!

With the main fabrication work completed the chassis was put into a basic primer ready for the dry build to begin. At this point in the build all suspension and drivetrain components were installed to ensure each aspect of the cars layout was suitably packaged and all systems positioned for optimum performance and balance.

This is the stage in Gobstopper III's development where the bulk of the real hard work is carried out and is vital in ensuring the final assembly goes smoothly.

Roger Clark though twe deserved a treat going into the weekend! This car is MEGA!

It is time to reveal Gobstopper III’s power unit! Built to a similar spec to the EJ20 based engine used to devastating effect in Gobstopper II, Roger Clark Motorsport’s 2.0L 900bhp motor saw Gobstopper II winning the Goodwood Festival of Speed Hill Climb in both 2015 and 2016! Setting a time just 0.3 seconds off Sebastien Loeb's 2014 winning time driving the Pike's Peak Peugeot 208 T16 in their first attempt! That was followed by overall victory again in 2016 this time fending off the McLaren P1 GTR LM hypercar of ex IndyCar racer Kenny Brack.

https://www.youtube.com/watch?v=ViDP0ZH3mm0

With a twin timing belt system, new custom twin plenum billet intake manifold, 200amp McLaren/TAG alternator and boosted by a Gen2 Precision 6466 turbocharger it’s a proven and reliable package now wrapped in an all new super-lightweight chassis!

The Roger Clark Motorsport Race Spec cylinder heads run without the use of traditional head gaskets, and instead using a special water/oil O ring sitting in a CNC cut groove on the head surface whilst combustion sealing is taken care of by an inconel gas ring at the top of each bore.

The RCM Gobstopper spec bottom end really shows how far you can push the OEM EJ20 closed deck block! They have been using this strong and reliable foundation for all of the Gobstopper engine builds since 2005 collecting x3 Time Attack Championships and x2 Goodwood Hill Climb titles along the way! Running aluminium Nikasil coated liners with RCM spec 75mm billet steel crank, conrods, head studs, pistons and main bearing configuration so they can run the engine safely at 900bhp for a full season without issue.

This same package was also used by Prodrive for Mark Higgin’s Isle of Man record attempt car which runs the Roger Clark Motorsport conrods, crankshaft, pistons and dry sump system.

To wrap up the powertrain series of images, here is a final shot of the completed Gobstopper III engine assembly patiently waiting to being lifted into its new home!

Finally one for you chassis guys! Gobstopper 3's double wishbone suspension uses in board Nitron Racing dampers for roll with a separate single damper to handle aero loading to avoiding the need to run overly heavy springs to stop the car grounding out in high downforce situations.

Also in shot is the electric power steering pump which helps keep the package as compact and lightweight as possible!

Yet another piece of British engineering excellence from official technical partner Alcon Specialist Brake & Clutch! Unlike the carbon/carbon brake system previously used on both Gobstopper I and II, the new 380mm carbon ceramic setup on Gobstopper 3 removes any requirement for a warm up procedure making it the ideal material for shorter sprints and hill climb events.

The 6 piston billet aerospace grade aluminum alloy calipers are machined for strength, high stiffness and super lightweight. When combined with the carbon ceramic discs this kit offers similar weight saving advantages of a full carbon/carbon kit but with far superior performance when cold.

Front Caliper – 2.54kg

Rear Caliper – 2.02kg

Front Disc Assembly – 5 to 5.5kg (carbon ceramic can have weight variation)

Rear Disc Assembly – 4 to 4.4kg (carbon ceramic can have weight variation)

There is plenty of exotic materials on display at the rear of Gobstopper III! The center exit exhaust system is constructed using 0.7mm Inconel and expels gases efficiently into a low pressure area at the rear of the car above the main carbon aero tunnels through its 3.75” bore pipework.

Packaging the suspension components amongst the T45 steel chassis and advanced aero pieces in Gobstopper III was certainly a challenge but again official technical partner Nitron Racing Systems worked closely with the RCM team to supply a compact, dyno tuned spring and damper combination more than capable of handling the downforce loading this car will generate on track.

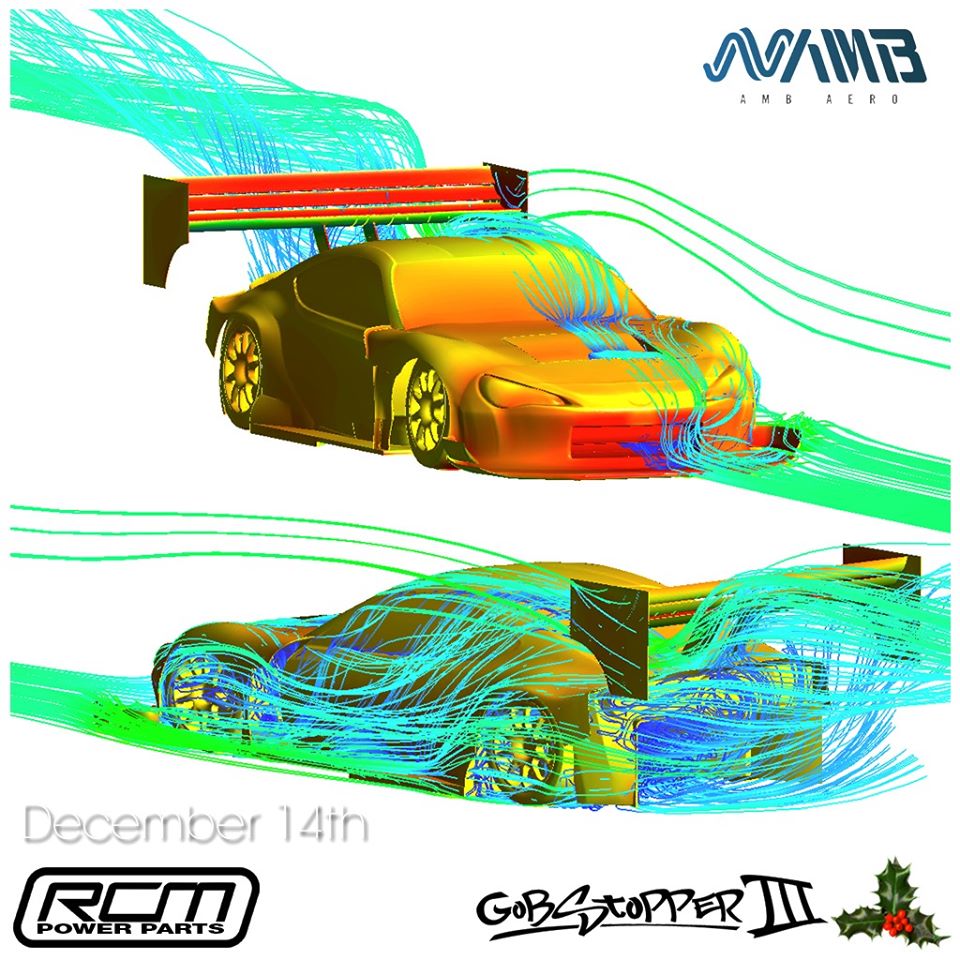

Whether it be F1, WRC or MotoGP over the recent years it’s become very clear that maximizing the advantages offered by improved aerodynamic design has become the most important area of development when chasing the ultimate lap time.

Andrew Brilliant of AMB Aero, already synonymous with many successful projects in World Time Attack as well as other high level motorsport disciplines, was brought on board at the time the chassis was being built.

Tasked with producing an aero package for Gobstopper III, AMB Aero using the latest CFD modelling techniques, were able to accurately simulate aerodynamic effects against the cars body shape continually refining each piece to achieve a package which perfectly balances both high downforce with a minimal overall drag factor.

Using the BRZ body design as the basis for Gobstopper III meant the team at AMB Aero already had a very compact and slippery shape to work with from the start. Lending itself nicely to the project's main target of ultra low weight and perfect weight distribution the challenge was then to apply the comprehensive aero package in such a tight and complex chassis.

Some of the events this car will compete in require a body design without overly large protrusions from the main body silhouette so a maximum width of 2m was set to ensure the cars performance would not be restricted by tight and narrow circuits.

The area most difficult to make a reality without compromising the original design was the large rear diffuser and underbody aero tunnel section which is required to navigate a whole host of rear suspension and chassis components!

This picture gives more of an insight into Gobstopper III’s comprehensive AMB aero package! With a substantial 47% of the total aero effect generated by the front splitter, floor area and rear diffuser its crucial to allow air to move away from the front wheel arch areas to retain the cars aero efficiency.

Careful positioning of the major engine and drivetrain components at the design stage of Gobstopper III was paramount in creating a car with optimized weight distribution. The off center location of the flat 4 EJ20 engine low down and much closer to the driver almost results in a mid-engine layout which coupled to an advanced 4WD system making it ideal for sprints, hill climbs and Time Attack!

Gobstopper III Mission Control! From behind the carbon Reverie steering wheel and Motec C187 dash the driver has easy access to x7 12 position trim switches which allow for extensive adjustment over various aspects of the cars setup. This means the driver can quickly dial the car in to any type of circuit, weather or grip level possible!

Mounted atop the engine and transmission covers which form part of the partition protecting the driver from any potential mechanical failure the dash panel allows the driver to fine tune the following parameters:-

Anti-Lag, Engine Calibration, Traction control, Launch control, Centre Diff, Boost, ABS

A carbon Kevlar hybrid composite material was chosen for the interior panels as it combines the high strength and stiffness of carbon with the high impact resistance of Kevlar.

Touchdown! At a whopping 2 meters in width Gobstopper III’s triple element carbon fiber rear wing is the highest down-force spec available from British race car constructor DJ Racecars.

The wing working in conjunction with the front splitter, flat floor and rear diffuser make up an aero package which produces a CFD estimated 2200kg of down-force at 160mph!

Final assembly and one of the last photos of Gobstopper III before finally being dressed in its carbon fiber bodywork!

Every material specified and component used in the Gobstopper III project is designed for pure uncompromising performance focusing on a targeted power to weight ratio which should see a marked improvement over existing lap times!

With the car due on the scales any day we’ll soon see whether we have achieved our goal!

Gobstopper III runs a specially commissioned fixed version of the normally adjustable Alcon GT spec pedal box. With the driver heel plate removed the clever modular design will initially allow us to run with the use of a normal clutch pedal. However in the future using the Alcon system means this can be easily removed when the car switches to a two pedal auto clutch system similar to those used in championship winning GT3 cars.

Smaller, lighter and more aerodynamic than ever before there’s one feature that will remain constant for Gobstopper III and that’s the simple yet distinctive Subaru Pure White paintwork expertly applied by Normandale Specialist Paint Spraying in Daventry.

Carbon and White certainly appears to be a winning combination!

Neatly packaged in its own carbon fiber case and positioned on the left hand side of the car to further aid handling by offsetting the drivers weight sits Gobstopper III’s custom made Kevlar fuel cell.

Holding 22L of race fuel the flexible crash resistant cell is designed and engineered to meet the highest safety standards by UK based motorsport fuel system specialist Premier Fuel Systems. From here the fuel is fed to the rails via a Protec Cobra pump and finally x4 1400cc ASNU high flow injectors supply the 900bhp EJ20’s thirst for VP Import!

Merry Christmas and a very Happy New Year from team Roger Clark Motorsport to all of our customers! Thanks for all your amazing support this year! We look forward to unleashing Gobstopper III when testing starts in March. See you all in 2020!

So back to work and what an exciting start to 2020! For the first time Gobstopper III is moved off its build table and somehow manages to look even better sat on the workshop floor!