We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Flatirons Tuning at the 2020 Pikes Peak International Hill Climb

Pikes Peak is race that is unique in a number of ways. One of the more interesting ones is that it has the ability to find weaknesses in your car that you most likely never would have found if you weren't running up Pikes Peak.

Part of this is because of the elevation and environment of Pikes Peak itself. But part of it might be that Pikes Peak is a close personal friend of Murphy, and being so, is eminently familiar with all of his laws so that it can enforce them whenever necessary.

For instance, in our 2019 run up Pikes Peak, after a routine shake down at High Plains Raceway just before race week we discovered a whole lot of glitter (bearing material) in our oil as we were changing fluids, which left us scrambling to get a new shortblock installed in order to make the race.

The team was able to get the car sorted out, and the engine that failed was the one that the car came off the assembly line with. It had a bit over 3,000 (mostly race) miles on it, and it had been reliable for 5 runs up Pikes Peak. So even though the timing was far from ideal, it was not a huge surprise that the engine had reached the end of its life.

Having an issue with bearing failure can often be related to oiling and oil pressure. This is a race car after all that sees a lot of hard use, and a fair amount of lateral g-force, and we are only looking to push that level of grip and performance harder. In preparing for Pikes Peak 2020, we decided to put a good deal of focus into our oiling system, and that meant installing Roger Clark Motorsport's new 4-Stage Dry Sump Oiling System.

We had a few other things on the agenda to improve the brakes and handling of the car too.

We finally decided to move up to 18" wheels to allow us to fit wider tires for more grip. In doing so, we swapped out the 5x100 WRX hubs for STI 5x114.3 hubs to give us bigger, more durable wheel bearings, as well as a much wider selection of wheels. This also allowed us to finally install the Wisefab front knuckles that we had discovered would not work with our 17" Enkei RPF1 wheels. The Wisefab Front knuckles also allowed us to keep our WRX suspension, which was helpful. The 18" wheels also gave us more room for even bigger front brakes, and for that we selected the Roger Clark Motorsport/Alcon 365mm front brake kit.

Installing the Roger Clark Motorsport dry sump system proved to be a bit more involved than we had anticipated because of how much you have to consider in terms of tank size, placement, and then the lines to and from the tank to the pump. But as August approached, the car was just slightly behind schedule to start testing.

The Pikes Peak Hill Climb opens up the mountain for testing a few weeks before the actual race week, and we had the car ready to run on our first Saturday of testing. The first two runs were starting to show us that we had more to work on in terms of the breather tank, and oil level with the dry-sump tank. But the handling of the car was definitely improved.

But then on run 3, things got a little more interesting. We were testing on the bottom if the course on Pikes Peak which is the start of the race. When the car is released, there is a left hand turn where you then cross the start line and your time starts.

On that corner for our third run, one of our water pump fittings came loose and we ended up dumping a good portion, if not all, of the water that we had in the cooling system as the car rounded the corner to the start line. From that point, the next problem was that the temperature sensor that we were using was in the upper coolant hose to the radiator, and with no water there to measure, it looked like temperatures were fine when they were anything but. By the time that the oil heated up to peg the needle on the oil temp gauge, the damage had been done. This was only a roughly 3 mile section of the course, so the car had been run with no coolant for just a couple of minutes, but the damage was extensive. Basically everything in the engine was a total loss.

This was just 2 weeks before race week, and we once again were left to put in an entirely new engine this time if we were going to make the race. The somewhat small positive note was that all of the braking and handling changes that we made to the car made a huge difference. Our driver, Scott Crouch, loved the new turn-in that the car had, and the overall grip of the car was significantly improved.

Everyone on the team did a fantastic job, and Sam Nelson who is a tech at Flatirons Subaru did his usual lightning fast work on getting the old engine out, and the new engine into the car. Roger Clark Motorsport was a huge help, and were able to send us another dry-sump pump so that we didn't have to risk running the first one that saw oil temperatures that were well beyond the scale of our temp gauge before it could be properly gone through.

The car was up and running a couple days before we had to put it in the trailer to make tech inspection, and we even put in about 20 break-in miles on the engine to shake it down first.

Once we got into race week, the car ran fairly reliably. It was clear that the car was going to be able to put down a good time this year, but we were struggling to find a good balance of oil level and our breather tank for the oil to keep the car from filling it up. In talking to some of the other teams on the mountain, it sounded like this was a somewhat common learning curve with a new dry-sump system. Cole from JC Fabworks had a spare tank that was a taller design that ended up helping quite a bit.

As we kept working to get the oil tank issue sorted, the car ran and put down good times for the most part. The only other issue that we noticed from time to time was coolant temperatures that were a bit higher than we would like. This is fairly common for Pikes Peak because of the elevation, and we hoped that the temperatures would stabilize on race day when we were making our run.

Once Sunday finally arrived we didn't have to wait too long for our turn to run up the mountain. The conditions were clear and warm, and it was just about as close to ideal as Pikes Peak will typically allow on race day. Scott took off in the car, and put down a fantastic first and second sector time. But as the course slowed down and got technical above Glenn Cove, the coolant temperatures started to creep up again. It was hard to tell from the times, but Scott said that he did have to lift off a bit to allow the coolant temperatures to cool down.

But even with all that, he still kept up a rapid pace at the top to finish the run.

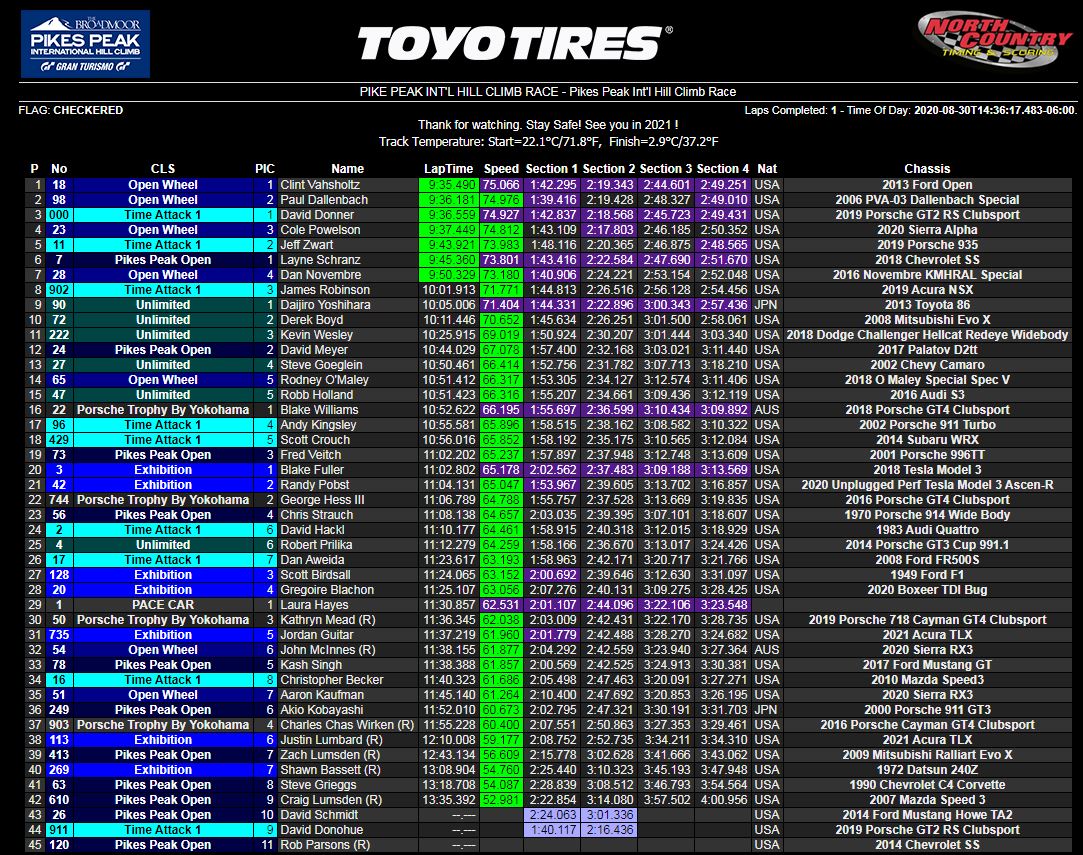

In the end, Scott put down a time of 10:56 which was 27 seconds faster than our previous best time which gave us a 5th in class finish which is also our best result to date.

This was our 9th hear running up Pikes Peak, and I'd say that it was also one of the most challenging to date. We had a great result to be sure, and we also know what we need to work on to continue to improve for next year.

None of this would have been possible without our team, sponsors, and supporters. A huge thanks goes out to:

Flatirons Subaru

Boost'd Scoops Motorsports

Roger Clark Motorsport

2020 was a great year for us on Pikes Peak, and we're all ready looking forward to 2021!

- The Flatirons Tuning Team